The Aviko Field to Fork Journey

Field to Fork

At Aviko we’re proud of our field to fork journey. how a seed potato, (tuber) ends up being the product that our customers love. Along the process efficiency is maximised, high quality is prioritised, and sustainability is crucial.

The field to fork journey begins and ends with a potato, but each stage along the journey adds value to ensure the product is of the highest quality and meets the demands of our customers.

Growing & Harvesting

The journey starts with a seed potato (tuber) but even before this is planted, time and care has been taken to ensure that only the best varieties of potatoes are used. Aviko’s potato varieties are: Bintje, Agria and Innovator, the latter being a young variety that replaced and improved some previous types with better characteristics.

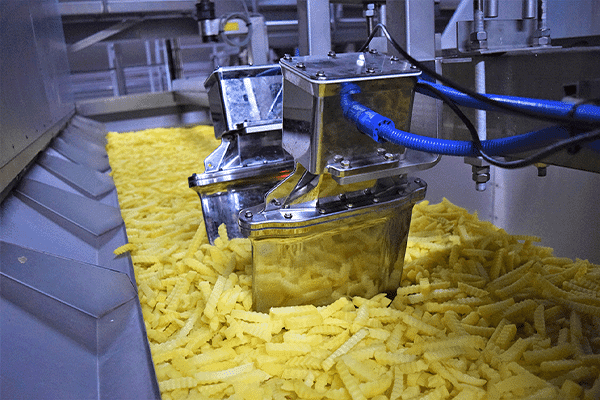

Processing

The potato has now entered the factory and will begin to be processed. Now it’ll be washed, sorted, peeled, sliced, blanched, dried, pre-fried in vegetable oil, frozen before being packaged. Our plants process 1,700,000 tonnes annually in facilities that are gluten-free.

Packaging

Now the potato is starting to resemble fries, it’s time for the product to be packaged. The products are packed carefully in user-friendly and recognisable packaging made from high-end materials. Our packaging generally shows additional information on different preparations.

Also, 82% of our primary packaging materials is recyclable and we’re aiming for all our packaging to be recyclable by 2025

Transport & Distribution

There are five factories in the Netherlands, as well as Aviko Group production locations in Germany, Belgium, Poland, Sweden and China. Aviko has an excellent logistics network for its global operations, to ensure our products reach more than 110 countries worldwide and bring joy to 2.5 billion tables.

Once the finished products have reached your kitchen, the focus in on you to choose how to use them.

Interested in finding out more? Contact us here